Since 1990 Cees Beers has been conducting research, development, and and testing activities in many areas of human and cycling performance, with special emphasis on aerodynamics. Main areas of expertise include aerodynamics, stress testing, electron surface scans, and training software. Aerodynamics Air Flow and Drag in a Rider's Position on the Bike - Notice the "tufts" in the rider's uniform (the photo at the right) that make visible the air flow. This type of wind tunnel testing quickly reveals "problem areas" in a rider's position and allows us to find the most efficient position (and uniform material). We perform these test from 0- to 30-degrees of attack. After testing, we translate the wind tunnel data in computer models and CFD (computational fluid dynamics) calculations, as shown in the graphs below.

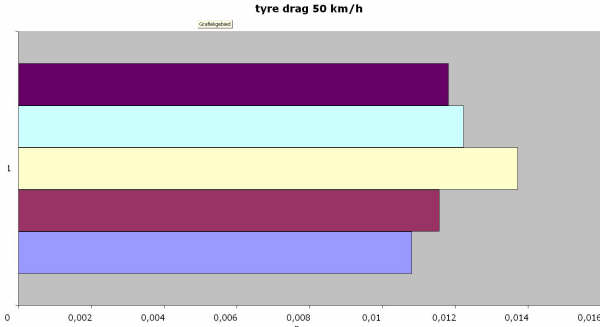

Aerodynamic"drag" of frontal area of five different tires - After testing, we translate the wind tunnel data in computer models and CFD (computational fluid dynamics) calculations. For example, the graph below illustrates the clear drag difference in frontal areas for five different tires. We also conduct 3-D (three-dimensional) measurements of force and tire rolling coefficients.

Free Speed - The graph below illustrates the drag coefficients (at different angles) of three bike frames, each with the same components and wheels. You can see that there is a huge difference between upper (red) line of frame #1 and and the lower (yellow) line of frame #3. The difference is about 35 watts at 50 km/h (this is what we call "free speed.")

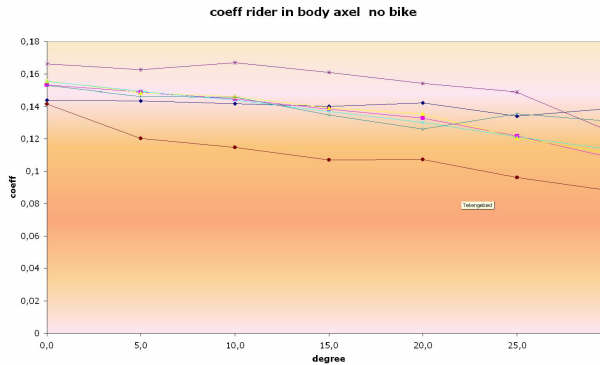

Rider "Isolation" - The graph below shows the drag coefficient of a rider, from 0 to 30 degrees. Here we can isolate the rider from the bike, to reveal advantage (or disadvantage) of of different positions. The lowest line indicates the most efficient aerodynamic body position for this rider.

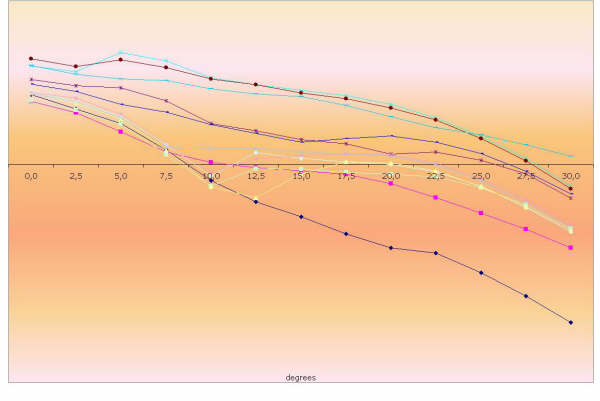

Aerodynamic Behaviors of Wheels at Increased Angles of Attack - In the graph below you can see a typical plot of the aerodynamic differences between wheels. For example, look how turbulent becomes the airflow around the "dark blue line" wheel at a 12.5 degree of attack. And notice how the "light blue line" wheel (the line at the top) exhibits are very efficient and predictable laminar flow even as the the degree of attack approaches 30 degrees.

Smoke-stream Analysis - The stream of smoke (coming from the "top") allows us to observe the laminar flow of air around our wheels (i.e., does the airflow "attach" to the surface, or is the flow full of turbulence.) The wheel on the right is ADA's newly developed stiff, flat-spoked, 780-gramm carbon wheel. Notice how tightly the airflow attaches to the wheel's surface. The testing showed that the flow remains attached to the surface all the way until a 30-degree angle.

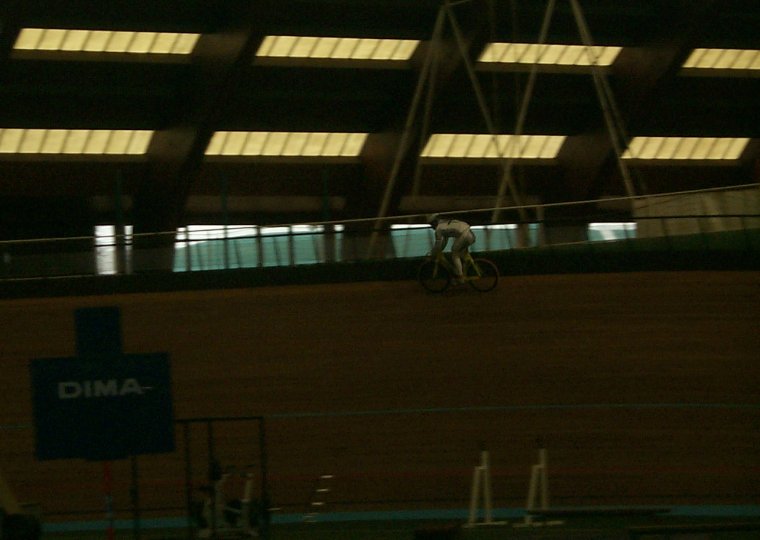

Real-conditions testing - We are conducting continual research into the ideal aerodynamic properties for road racing. Using the wheel pictured below, our testing will determine whether this wheel's aerodynamic properties are suited for normal road racing conditions.

Wheel testing at the French Training and Sports Development Center

Stress

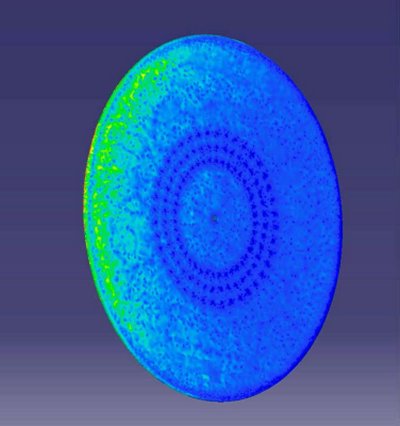

Testing Stress Testing - This is how we perform a three-dimensional (3-D) stress test of 120 measuring points on an ADA carbon wheel. Our testing also allows us to verify the accuracy of our finite element analysis (FEA) calculations by comparing it with real-world data.

CFD calculation of ADA wheel.

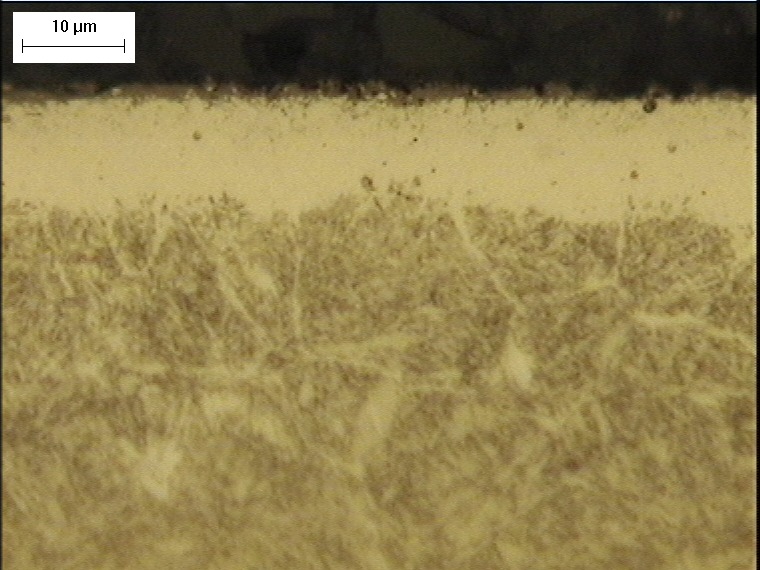

Electron Surface Scans The scan below shows the material structure of ADA bottom bracket axles. The narrow lubrication channels are visible. This test was used to determine an ideal solid lubricating agent that is both super slick and wear resistant. We were searching for an extremely efficient lubrication that will last for the life of the bottom bracket without need for re-lubrication.

The surface scan below reveals the thickness of the layer of ADA-Philcoat, which is a super-hard and slick surface originally used for racing speed skates. ADA-Philcoat was developed jointly by ADA and Philips Laboratories, and our tests have shown that it is an ideal lubricating agent when applied to the surfaces of axles in ADA bottom brackets and hubs.

Microscopic sample of high-quality carbon layer of ADA products

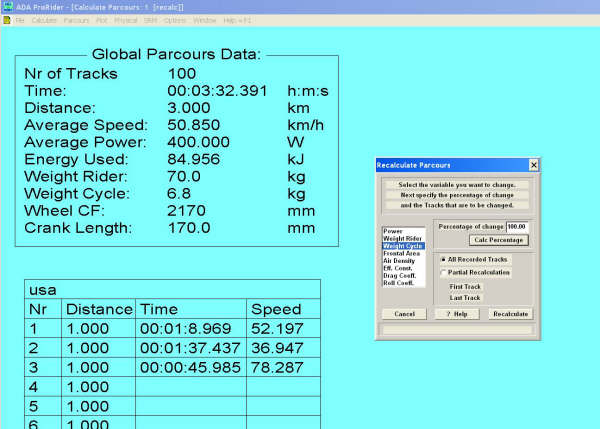

Training Software ProRider Training Software - Riders working with ADA also have access to ProRider training software. A product of thousands of hours of development over more that 15 years, this sophisticated training aid allows a rider to experiment "in the lab" with dozens of variables in order to determine the optimal combination for a particular race. For example, ProRider software can accurately predict the performance differences that will result from changing rider position, rider weight, bike weight, wheel weight, air temperature, air pressure, humidity, power output, and tires.

With this handy ProRider interface we can enter numerous variables that allow us to predict a rider's performance. The results enable us to recommend equipment and gearing that will yield the best performance on a specific course. The powerful algorithm in ProRider software make it possible to change a variable (for example, a different frame, wheel, rider weight, etc.) and instantaneously calculate the resulting change in performance.

After we have some standard rider parameters, we can then predict a rider's performance on any course, form a local crit to a monster climbing stage in a major tour (such as a L'alpe D'Huez time trial). For more information about ADA Research and Testing Services, contact Cees at ada.prorider.org. |